About Us

Founded in 1980, Chimera designs and handcrafts unrivaled lighting products that provide soft and beautiful illumination for the professional image maker in film, video, and still photography.

Our Quality

Our products are among the most reliable in the industry and found in production rental shops even after decades of use. One of the hallmarks of the Chimera brand is the exceptionally high-quality standards that go into creating every product. Materials are sourced and produced in the United States to ensure that Chimera’s Lightbanks, Speed Rings and other products meet the company’s uncompromising standards.

Our Shop

Proprietary materials and superior workmanship guarantee that every Chimera product will be durable and long lasting. Handcrafted for over 40 years, all products are designed, sewn, and assembled locally at our Colorado USA headquarters. Meticulous inspection prior to shipping guarantees that each piece of gear is perfect before it reaches the customer.

The History of Chimera Lighting

How It All Began

From its inception in 1980, Chimera Lighting has gained a reputation for innovation and excellence in the photography and film industries for its exceptional lighting products. But, like many innovative companies, Chimera evolved from humble beginnings.

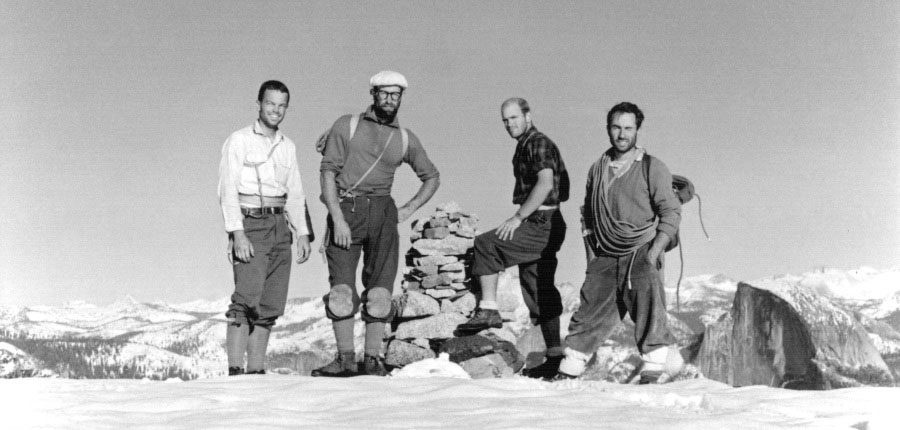

Company founded with first collapsible fabric Lightbank

Photographer Gary Regester is tired of lugging foam core boxes on location. He gets a big idea: create a collapsible soft box that can be fitted on lights. He collaborates with mountaineering engineer Tom Frost. The result? The Illuminata Lightbank, with an innovative “feet and strap” set that makes it easy to attach to strobe lights.

1980Company founded with first collapsible fabric Lightbank

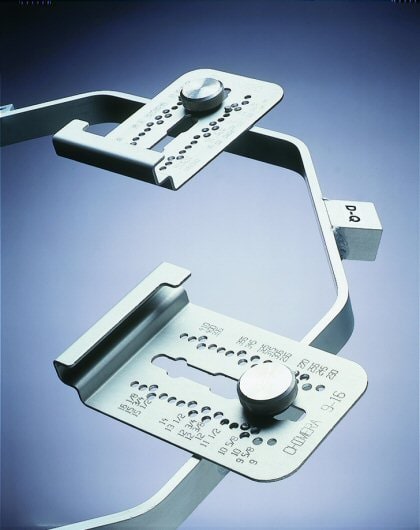

Speed rings allow one Lightbank to be mounted on multiple light fixtures

Chimera takes a good idea and makes it even better, introducing the industry's first Speed Rings—16 in all!. The industry rejoices, while the competition groans.

1983Speed rings allow one Lightbank to be mounted on multiple light fixtures

Super Pro introduced – silver lining recessed front screen

Chimera introduces the first Super Pro Lightbanks, with silver interior and a recessed front screen, making the lightbank more directional. It also bears the signature Chimera trademark: Velcro™ racing stripes!

1985Super Pro introduced – silver lining recessed front screen

Honeycomb grids for precise control

Chimera creates the first honeycomb grids, offering unparalleled precise control.

1986Honeycomb grids for precise control

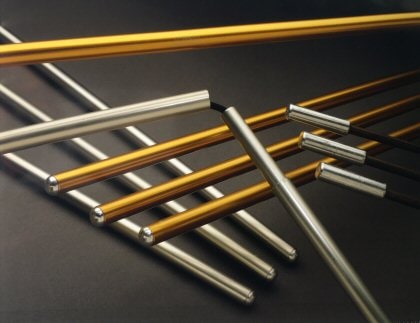

Improved Aluminum & steel poles – Speed Rings upgraded to allow rotation

Two more industry breakthroughs! Chimera introduces new and improved aluminum and stainless poles, engineering a proprietary process for stainless steels rods that provide flexibility and strength. We also introduce the industry’s first rotating Speed Rings, so photographers can “tweak” the position of a Lightbank.

1987Improved Aluminum & steel poles – Speed Rings upgraded to allow rotation

Quartz & Daylight Lightbanks using high heat materials used in Hollywood for the first time

Chimera invents film Quartz and Daylite Lightbanks, and breaks into the Hollywood scene for the first time, with gaffer Mo Flam using our equipment while filming Fried Green Tomatoes.

1990Quartz & Daylight Lightbanks using high heat materials used in Hollywood for the first time

Video Pro and Daylight Jr

Chimera Video Pro Lightbanks and Daylite Juniors make a splash in the industry. Chimera continues to fine tune and innovate products for the film industry, introducing new products almost every six months.

1992Video Pro and Daylight Jr

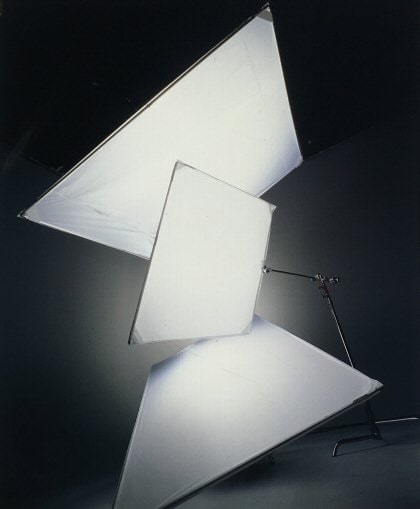

Panel Frame system developed

Versatility rules, and Chimera Panel Frames are King! Bungee-corded together to prevent lost pieces, they can be used as black-out, reflector or diffuser. And with 18 unique Chimera window patterns that can attach to the frame-mounted holder, the wide range of creative uses is endless.

1995Panel Frame system developed

Lanterns

Recognized for portability and durability, Chimera’s new lanterns also deliver simplicity for solutions in omnidirectional soft lighting.

1996Lanterns

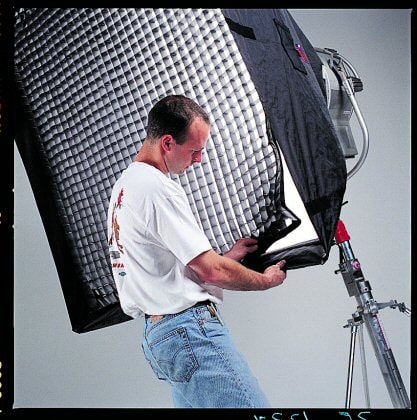

Plus Banks and Fabric Egg Crates

Lightbanks evolve to Plus Banks. Chimera introduces removable front screens with different densities, offering new dimensions in lighting for industry pros. Chimera also revolutionizes modifying soft light, with the introduction of Fabric Egg Crates. Chimera claims its spot as the industry leader.

1997Plus Banks and Fabric Egg Crates

Adjustable rings

Another Chimera innovation delights image makers and rental houses alike. We introduce two more must haves: Adjustable Speed Rings for film/video Lightbanks and Dual Block Speed Rings, which conveniently fit both Quartz and Daylite Banks.

1999Adjustable rings

Pancake Lantern introduced

Chimera introduces the industry’s first Pancake Lanterns! What will we think of next?

2001Pancake Lantern introduced

Octaplus 5/7 two-in-one

Chimera delivers two more break-through products: our amazing Quick Release Speed Rings and the OctaPlus 5/7 Lightbank, a two-in-one size solution that’s the only convertible in the industry.

2005Octaplus 5/7 two-in-one

Triolet & Birdcage w stand adapters

The folks at Chimera do it again, with three big ideas! Our Birdcage Lanterns deliver a truly versatile soft light source, the Triolet Light provides a truly versatile continuous light source and Chimera Stand Adapters—including a unique dual axis version.

2007Triolet & Birdcage w stand adapters

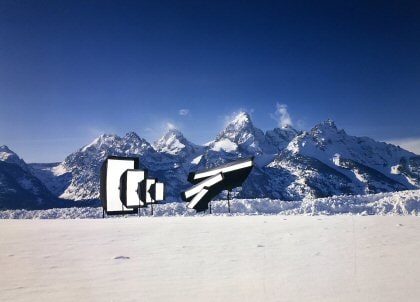

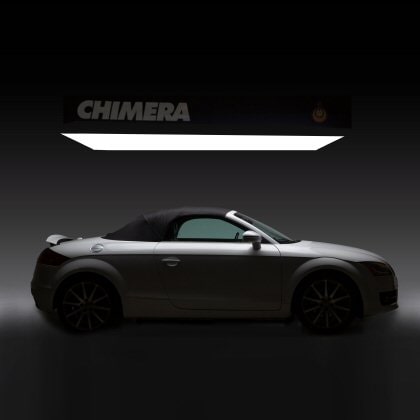

F2x overheads

Chimera creates the F2x, giving photographers perfect light for BIG ideas.

2009F2x overheads

First collapsible Beauty Dish

When it comes to portrait photography, many professionals reach for the well-loved beauty dish. When the time comes to hitting the road, Chimera's Octa Beauty is an easy companion - you never have to sacrifice perfect lighting for portability again.

2010First collapsible Beauty Dish

Tech Banks - Lightbanks for LED panels introduced

Chimera does it again with portable, easy to use Lightbanks. Chimera's TECH Lightbanks are designed to compliment the new advanced lighting technologies now and in the future.

2012Tech Banks - Lightbanks for LED panels introduced

Partnership with Lighttools

With Lighttools' soft fabric grids, the light is contained where you need it most. ez[POP] Soft Egg Crates combine innovation in lighting and setup with a built-in tensioning frame to keep your grid in place.

2016Partnership with Lighttools

POP banks introduced for popular 1x1 & 1x2 panel style LEDs

The POP bank launches Chimera’s range of frameless Lightbanks! Designed specifically for the newer square and rectangular panel style LED fixturess, it simply slides over the front of your fixture without the need for speed rings or mounting hardware. How easy is that?

2017POP banks introduced for popular 1x1 & 1x2 panel style LEDs

Powered by LiteGear - Panel Lantern and F3

Portable LED Lighting solutions that combine the innovative LiteGear LED technology with the tried and true reliability of Chimera Lightbanks; the Panel Lantern packs a whole lot of versatility in a very portable package on location or in studio and Chimera's new F3 is the next evolution of overheads.

2018Powered by LiteGear - Panel Lantern and F3

Eyes on the future

After a halt on filmmaking in 2020, Chimera emerges from the shadow of the Covid 19 pandemic with robust sales and a resolve to continue serving our users with products of premium quality and long-lasting performance. Still handmade on-site here in Colorado, USA, we continue to partner with today’s popular light manufacturers to give you innovative and inspiring tools to create your masterpieces.

2021